One element and two element aerosol filling machine

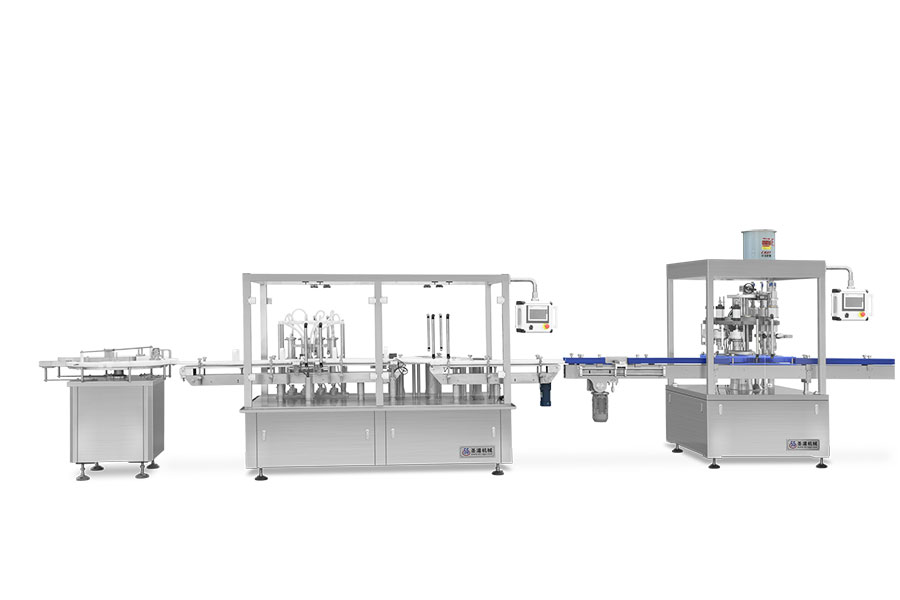

Product description: The equipment is shown in the following figure1:

The products configured for this production line include (from the front to the back): rotary high-speed valve unit, centrifugal high-speed valve sorting machine, valve supply elevator, 6-station high-precision measuring cylinder&single group booster pump, 6-head sealing&6-head inflation integrated machine (positive pressure explosion-proof electrical box and explosion-proof human-machine interface). It has the advantages of simple operation, friendly human-computer interaction, and fault indication. Easy to troubleshoot and troubleshoot.

2. Production processes and performance parameters completed by each unit:

A. The rotary high-speed upper valve unit is shown in Figure 2

Figure 2

Model: SG-QGQW25-150HSF rotary high-speed valve upper machine, developed from advanced foreign equipment technology with 16 workstations. The unit consists of a valve elevator, a rotary disc type centrifugal valve machine (customized according to valve form), and a high-speed rotary valve upper machine. The working principle is that a valve delivery track sends the mist valve to the corresponding filled mist tank under the main transmission star disk. There is a valve extraction device on the main star disk that guides and positions the valve before sending it to the mist tank. The entire process is continuous and uninterrupted. The main process purpose is to add an aerosol valve to the aerosol tank after liquid filling and transport it to the next workstation. This device has the advantages of stable operation and convenient adjustment.

Equipment parameters:

Valve speed on the valve: 0 to 150 pieces/minute

Adaptable valve: 1-inch aerosol without straw valve (this equipment is designed for your company's products)

Diameter of aerosol canister: φ 35mm to φ 66mm

Height of aerosol canister: 45mm to 260mm

Gas source pressure: 0.7 to 0.8Mpa

Higher gas consumption: 1.5m ^ 3/min

Power supply 220V AC, power 1.5KW

Figure 3

Model: SG-QGQW25-150FC explosion-proof sealing and inflating machine: composed of 6-head sealing and 6-head inflating integrated machine, 6-head high-precision measuring cylinder&single group boosting cylinder, and positive pressure explosion-proof electrical cabinet. The process flow completed by this equipment is as follows: the front high-speed valve machine is transported to this unit through a flexible chain plate, and the explosion-proof servo motor drives the indexing plate to work. Six sets of gas mist tanks with valves are positioned at once. The sealing unit works once to complete the capping, sealing, and resetting actions until the sealing is completed. The positioning disc is positioned again and divided into 6 stations to position the sealed tank to the inflation station, and then the metering cylinder, through the filling head, rushes into the aerosol tank under high pressure through the valve core. The adjustment is convenient by a pair of decelerating bevel gears and the hand wheel, and is indicated by a ruler. The single set of booster cylinders here is used to pressurize and liquefy the propellant and exhaust the air. At this point, all processes of the aerosol tank are completed and flow through to the next process flow. This device is equipped with a negative pressure suction device, which pumps the residual gas of the propellant (after inflation, the head air) to the filtration device (provided by the equipment manufacturer). Special note, your company's procurement requirement is for high-precision micro inflation units, which are non-standard customized types (inflation volume 3g ± 0.1g). The actual dimensions of the finished products produced and processed are smaller than the existing layout dimensions, only for high-precision measuring cylinder groups.

Equipment parameters:

Sealing and inflation speed: 80 to 150 pieces/minute (Note: This device is an all-in-one machine, and if the speed requirement is high, the number of inflation heads increases, it needs to be split: sealing machine+inflation machine)

Adaptable valve: 1-inch aerosol without straw valve

Sealing diameter: 26.9 to 27.4 ± 0.1 mm

Sealing depth: 5.2 to 5.6 ± 0.1 mm

Diameter of aerosol canister: φ 35mm to φ 66mm

Height of aerosol canister: 45mm to 260mm

Gas source pressure: 0.7 to 0.8Mpa

Higher gas consumption: 1.0m ^ 3/min

Inflation accuracy: below 20ml ± 0.5ml industry standard

Power supply 220V AC, power 1.5KW

Special Explanation: This equipment's high-precision metering pump is a specialized micro propellant metering pump, with accuracy standards (customer requires an inflation volume of 3g ± 3%, about ± 0.1g). The types of propellant are propane, butane, and isobutane.

C. High speed integrated cover installation equipment as shown in Figure 4

Figure 4

Model: SG-QGQW25-150GLT rotary high-speed connected cover automatic installation equipment, developed with advanced foreign equipment technology at 16 workstations. The unit consists of a connected cover elevator, a rotary disc type psychological cover machine (customized according to the cover form), and a high-speed rotary cover+capping machine. The working principle is that a valve delivery track sends the connected cover to the corresponding filled aerosol tank under the main transmission star disk. The cover extraction device on the main star disk guides and positions the cover before sending it to the top of the aerosol tank. The entire process is continuous and non-stop, and then the upper cylinder drives the pile head to press down to drive the connected cover into the aerosol tank. This device has the advantages of stable operation and convenient adjustment.

Lid sorting speed: 0 to 150 pieces/minute

Applicable valve: 1-inch aerosol valve (this equipment is designed for your company's products)

Diameter of aerosol canister: φ 35mm to φ 66mm

Height of aerosol canister: 45mm to 260mm

Gas source pressure: 0.7 to 0.8Mpa

Higher gas consumption: 1.5m ^ 3/min

Power supply 220V AC, power 1.5KW

Technical Parameter

technology project | Technical Parameter |

Applicable specifications | Φ35至φ66一英寸氣霧罐 |

Number of upper valve and pressure connected body covers | 16個頭(上閥)、16個頭(壓外蓋) |

Number of sealing inflatable heads | 6頭封口&6頭充氣一體機 |

production capacity | 封口充氣速度:150瓶/分鐘 加閥速度:150瓶/分鐘 ) 壓連體蓋速度:150瓶/分鐘 |

Sealing type | 一英寸內擴 |

Inflation accuracy | 20ml 精度±0.2g |

Upper valve qualification rate | ≥99.8% |

Qualified rate of upper body cover | ≥99.8% |

Power supply power | 封口充氣機:2KW,上閥機:1.5KW 上連體蓋蓋機:1.5KW |

External dimensions | 2500×1050×1850mm(封口充氣機) 940×870×1850mm(上閥機)940×870×1850mm(上連體蓋機) 設備尺寸以DQ確認為準 |

設備重量 | 約1500Kg(封口充氣機)約1000Kg(Upper cover machine, upper connected cover machine) |

Copyright ? 灌裝生產線官網 滬ICP備17000578號-2